Production Planning Report

To access the Production Planning Report, go to:

Home > Manufacturing > Reports > Production Planning Report

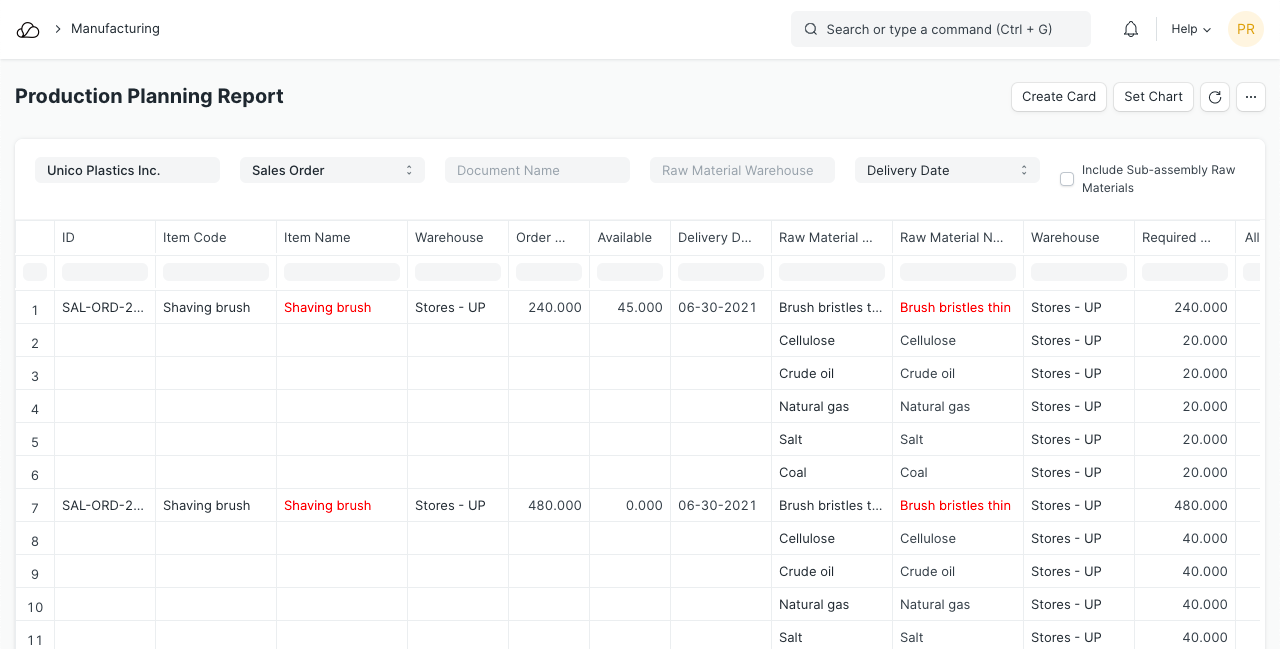

This report will help users plan the finished good as well as the raw materials against the Sales Order / Work Order / Material Request (with the request type as Manufactured) data. Mostly, in the case of make to order, this report helps you plan the production of the finished goods as well the raw materials.

Using this report user will get the information about the available finished goods as well as available raw materials that are required in the production process. The unavailable finished good or raw materials will be highlighted in the red color.

In this report system will allocate the available stock to the order based on the sorting. The Order By filter will be use to sort the orders based upon the Delivery Date, Order Amount.

For example, Bob works in the Furniture Manufacturing company. Their organization follows the make to order production planning. On Monday, Bob received the Sales Orders for tables and chairs from different customers. So Bob has checked the production planning report to check the availability of the raw materials and he found that either table or chair can be manufactured with the available raw materials. Bob used the 'based on' filter to know which Finished Good order's delivery date is earlier. He has found that he has to deliver the Table earlier so he has started working on it and his colleague has created the purchase order for raw materials which will be used to make chair.

Using the Production Planning Report, this report auto allocate the raw materials to the order once it's available in the respective warehouse.